How IoT is reshaping modern supply chains

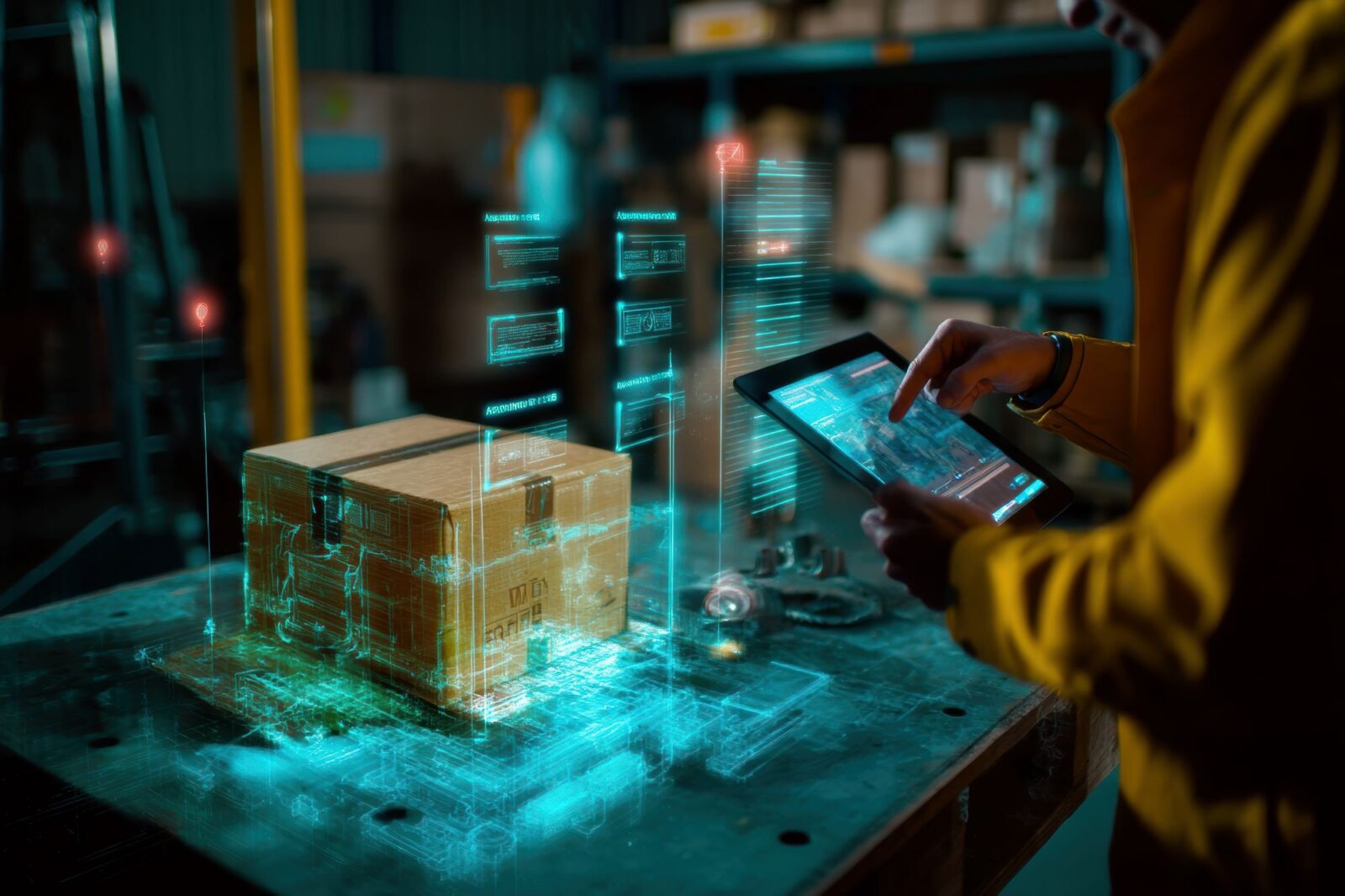

The Internet of Things (IoT) is often mentioned as one of the key technologies shaping the future of supply chains. But beyond the buzzwords, what does IoT really mean in practice—and why is it becoming so relevant for logistics, asset management and supply chain operations?

What is IoT?

At its core, IoT refers to physical objects that are connected to the internet and continuously exchange data. These “things” can be everyday consumer devices, but in a supply chain context they are typically assets such as pallets, containers, roll cages, vehicles or even individual products. By equipping these assets with sensors, trackers or smart labels, companies gain access to real-time information about location, condition and usage. This turns physical flows into digital insights.

What is the role of IoT in supply chain?

In supply chains, this connectivity creates a fundamentally different operating model. Instead of relying on manual scans, paperwork or assumptions, IoT enables a living, data-driven ecosystem where assets, transport and products communicate continuously. A pallet can report where it is and whether it has been exposed to damaging temperatures. A container can show how often it is used or how long it sits idle. Vehicles can provide real-time updates on routes, delays or driving behaviour. Together, these data points deliver a level of transparency that traditional systems simply cannot match.

What is the impact of IoT in logistics operations

This visibility has direct operational impact. Real-time tracking allows organizations to know exactly where their assets are—whether they are in use, in transit or lost somewhere in the network. Inventory management becomes smarter and more accurate, reducing manual counts, stock-outs and overstock. Issues such as delays, damage or temperature deviations can be detected immediately, allowing teams to intervene before small disruptions escalate into costly problems.

Beyond daily operations, IoT also supports longer-term optimization. By capturing the full lifecycle of assets, companies gain insight into usage patterns, rotation speed and overall performance. This enables better planning, higher asset utilization and more informed investment decisions. In effect, IoT shifts supply chain management from reactive firefighting to proactive, strategic control.

The role of IoT for your reporting and regulatory matters

Regulatory pressure is another area where IoT is rapidly gaining importance. New and upcoming regulations such as PPWR, EUDR and Digital Product Passports require reliable, time-stamped data on products and materials. IoT provides a solid digital foundation for compliance, replacing fragmented records with consistent, verifiable information. At the same time, it supports sustainability ambitions by making it possible to track circular usage, measure CO₂ savings and reduce waste across asset pools.

Benefits of IoT across various industries

The benefits of IoT are visible across many industries. Retailers improve availability and reduce losses. Transport operators optimize routes, increase fleet efficiency and enhance cargo security. Asset poolers gain tighter control over shared assets and significantly reduce shrinkage. Manufacturers and logistics service providers improve predictability, service quality and collaboration with partners. In practice, any organization managing physical assets or goods stands to benefit.

Ultimately, IoT is not just a technological upgrade. It represents a strategic shift in how supply chains are managed—towards greater transparency, resilience and sustainability. In an environment of rising costs, tightening regulations and increasing expectations around visibility, connected supply chains provide the insight and confidence businesses need to move forward.